Aerospace Robotic Marking Cell

Robotic Marking Cell for Aerospace – Automated Precision for Critical Components

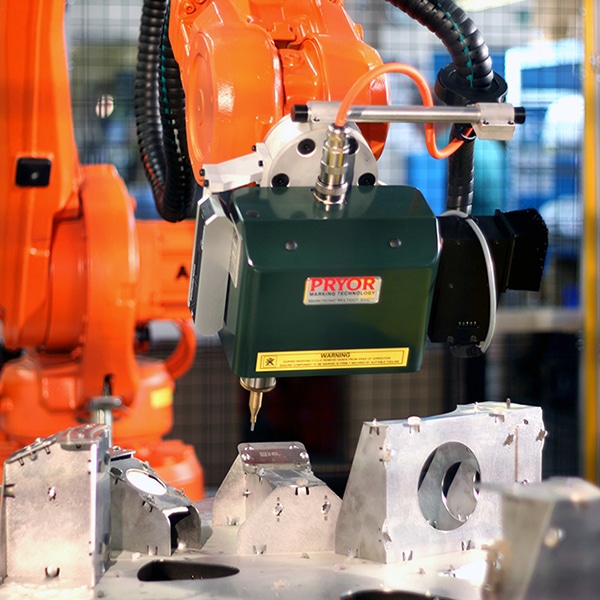

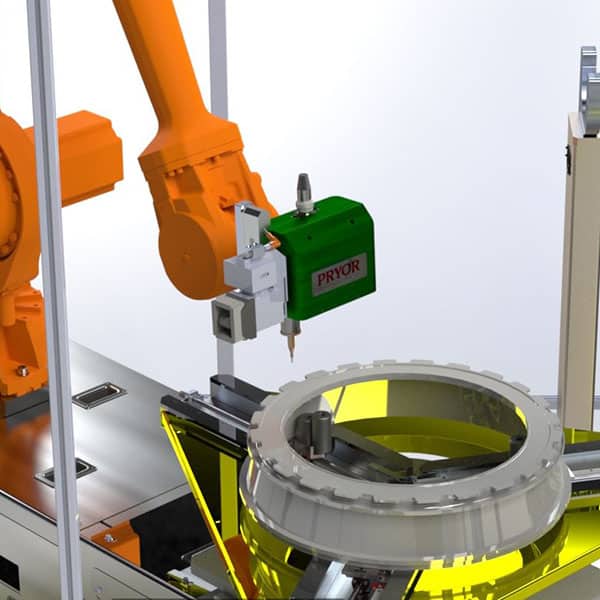

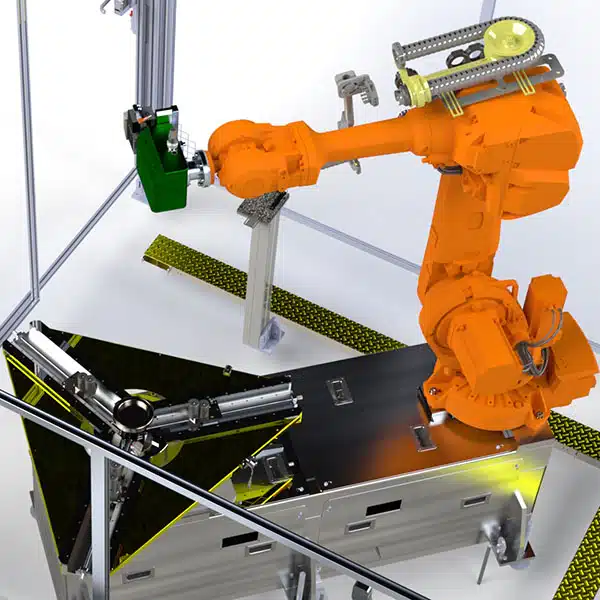

In the high-stakes world of aerospace manufacturing, the demand for absolute precision, consistent quality, and efficient traceability is paramount. Pryor’s Robotic Marking Cell represents the pinnacle of automated aerospace marking solutions, offering unparalleled accuracy and flexibility for identifying critical aero engine parts, large structural components, turbine rings, discs, BLISKS, and other complex components.

Designed to seamlessly integrate into modern production lines, our Robotic Marking Cells deliver automated, repeatable, and verifiable marks, reducing human error and increasing throughput. This is the ideal solution for aerospace manufacturers looking to optimize their aerospace marking processes and ensure full compliance with rigorous industry standards.

Elevating Aerospace Marking Automation:

The complexity and variety of parts within an aero engine, combined with high production volumes, necessitate intelligent marking solutions. Our Robotic Marking Cell addresses these challenges by providing:

Unmatched Repeatability and Consistency: Robots deliver identical marks every time, regardless of part variation within tolerance, ensuring consistent quality and compliance for every aerospace marking application.

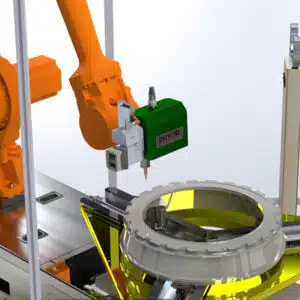

Precision on Complex Geometries: The multi-axis dexterity of a robotic arm allows for precise marking on curved, angled, or hard-to-reach surfaces, common in components like BLISKS, turbine discs, and various aero engine parts.

Increased Throughput and Efficiency: Automate your marking processes, freeing up valuable human resources and significantly increasing the speed of your production line, especially beneficial for high-volume aerospace marking tasks.

Enhanced Safety and Ergonomics: Remove operators from repetitive or hazardous marking tasks, improving workplace safety and reducing the risk of musculoskeletal injuries.

Full Traceability Integration: Seamlessly integrate mark data into your manufacturing execution systems (MES) and enterprise resource planning (ERP) for comprehensive lifelong traceability of all aerospace marking operations.

Key Features Optimized for Aerospace:

Integrated Marking Technologies: Our Robotic Marking Cells can incorporate a range of Pryor’s proven aerospace marking technologies, including:

Dot Peen: For deep, robust marks on demanding aerospace materials, ideal for serial numbers, part numbers, and Data Matrix codes on rings, discs, and other aero engine parts.

Laser Marking: For high-resolution, non-contact marking on sensitive materials or when intricate detail is required, perfect for BLISKS and fine component identification.

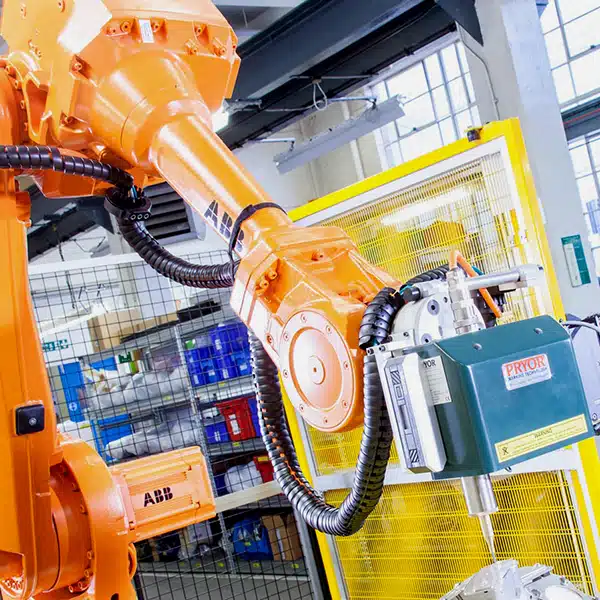

Advanced Robotic Solutions: Utilise industry-leading robotic systems chosen for their precision, reach, and payload capacity, ensuring compatibility with a wide range of aerospace marking applications.

Intuitive Software Control: Pryor’s specialized software provides easy programming and control of the robot and marking head, allowing for quick adaptation to new part designs or marking requirements.

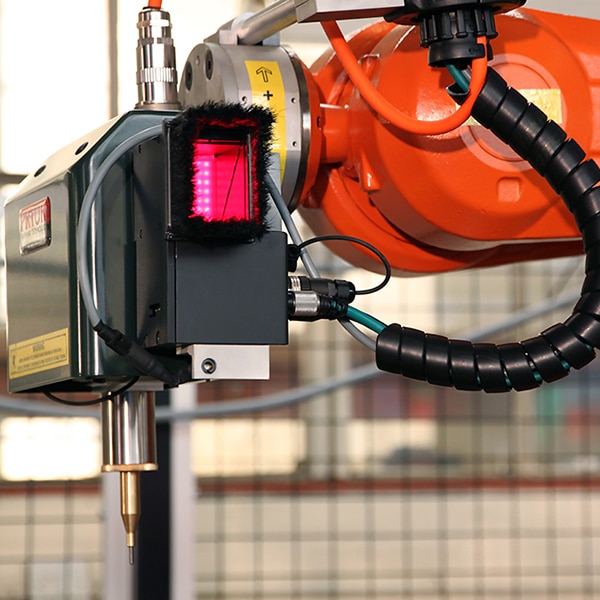

Vision System Integration: Essential for aerospace, our cells can include integrated vision systems for automatic mark verification, ensuring each mark meets specified quality standards (e.g., AS9132, JES131, AIM-DPM-Guideline, MIL-STD-130, ISO15434, ISO16022). This is critical for validating marks on high-value parts like BLISKS and aero engine parts.

Customizable Part Handling: Design the cell with appropriate fixturing, conveyors, and automated loading/unloading mechanisms to suit your specific aerospace component sizes and production flow.

Safety Interlocks and Enclosures: Fully enclosed cells with robust safety features ensure operator protection in automated environments.

The Pryor Advantage in Aerospace Automation:

Pryor’s extensive experience in providing cutting-edge aerospace marking solutions allows us to design and implement Robotic Marking Cells that are not just automated, but truly optimized for the aerospace industry’s unique demands. We understand the criticality of marking aero engine parts, rings, discs, and especially the complex contours of BLISKS. Our commitment is to deliver a reliable, high-performance, and compliant solution that enhances your manufacturing capabilities.

For aerospace manufacturers seeking to achieve the highest levels of marking precision, efficiency, and traceability, Pryor’s Robotic Marking Cell is the ultimate automated solution for all your aerospace marking needs.

- Features

- Video

- Technical Data

Features

- Robot moves can be programmed directly from windows interface without the need for PLC programming or robotics expertise

- Vision systems used to automatically identify components to be marked and trigger correct robot moves and marking sequence

- Vision systems used to automatically locate marks at offset distances from physical features

- Marking sequence can be triggered manually, or automatically from a variety of inputs, including sensing presence of component, barcode scan, RFID tag

- Eliminates operator error with automatic selection of mark sequence and verification of mark

Video

Technical Data

Systems configurable with most common third party 6 axis robots, depending on required reach and maneuvers of application.

Marking system end effectors designed to suit application.