MarkMaster Networked

Connect multiple PCs running the Traceability Software.

For maximum benefit use this tier with the Data Logging and Data Reporter feature of the Quality Control options.

Storage and management of marking layouts shared from a central server for peace of mind version control.

Cross-checking of ID marks across multiple marking locations to ensure all marks are globally unique.

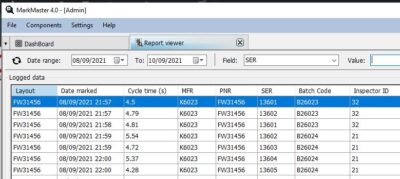

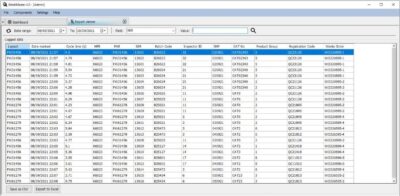

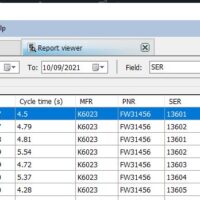

Central storage of all marking data across all stations. Search, sort and generate marking and traceability reports from any client PC on the network.

- Standard Features

- Applications

Standard Features

- SQL Server integration – All marking layouts, marking data and system configurations are stored centrally in the server database

- Database creation and table creation utilities available

- Marking machine calibration settings to allow multiple machines to share the same marking programs

- Assign programs to specific stations

- Central location for user profile configurations

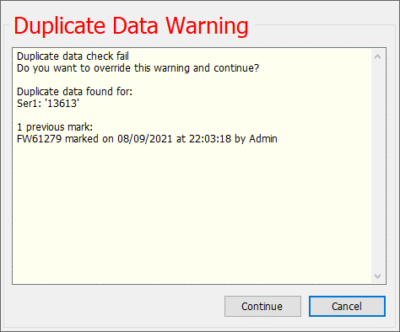

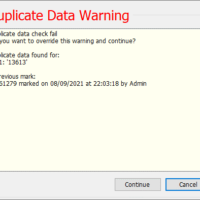

- Duplicate checking across all stations and sites to ensure marked data is never duplicated

- Unique global serial number allocation across all marking systems.

- Filter, Sort, Search and generate reports from all marking data across all marking stations. Export individual part details to pdf or a filtered sub-set of data to Excel

- Potential for other enterprise software to integrate with the traceability software database using SQL server tools

- Offline editing of marking layouts and simulation of programs can be done from any client PC on the network with the appropriate user privileges

- Quality engineers can create reports or investigate quality issues from any PC on the network

- If the server architecture allows, multiple sites can be connected to benefit from all the data sharing features

- Option to migrate non-networked (standalone) marking station data to the server to preserve legacy data

- PLUS all software features from other packages

Applications

- Safety critical component unique serialisation requirements

- Unique serialisation across multiple sites to meet the MIL-STD-130 globally unique marking requirements

- Quality engineer audit tools

- Customer compliance reports for the part mark and traceability process

- Standardisation of the marking process using shared, version-controlled marking programs