Mobile Marking Station with Tilting Head

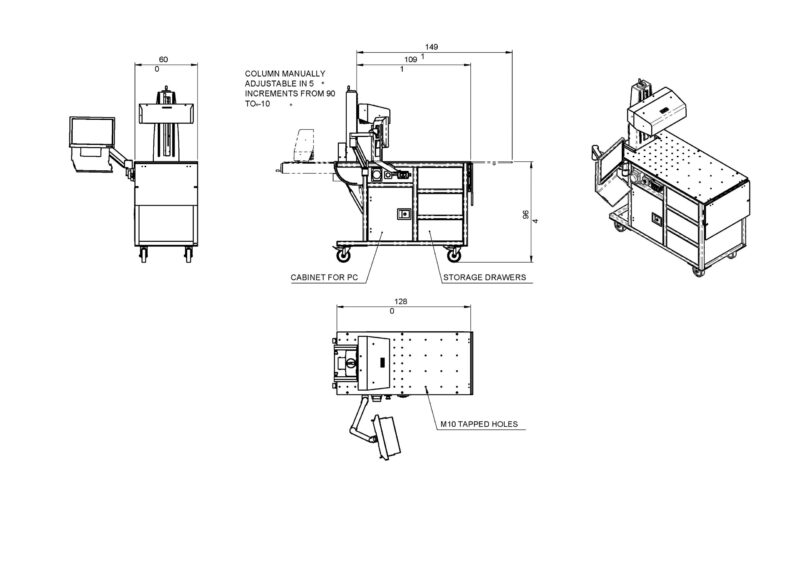

The Mobile Marking station uses a BenchDot marking head mounted onto a tilting column for ultimate portability and flexibility, it is ideal for low volume, high variety components. The marking head can be tilted from -10 degrees to +90 degrees meaning that marking on an angled surface is simple and straightforward. The table top is covered with a thick, industrial, non-slip surface to protect the cart and ensure the part does not move during the marking cycle. The top is drilled with M10 tapped holes at 75mm pitch for easy fixture attachment.

Programmed using the 4000 Controller orPryor’s PC based Traceability Software

- Available in 2 different marking window sizes

- Option to upgrade to an Electric Z Axis with Autosense (EZA) for increased quality control and operator ease

- Marking at pre-set, repeatable angles with autosense feature to accurately detect and repeat marking gap / force

- Flexible and quick change of fixtures for high variety of components being marked

- Mobile marking cart for use around shop floor, preventing movement of larger or critical components

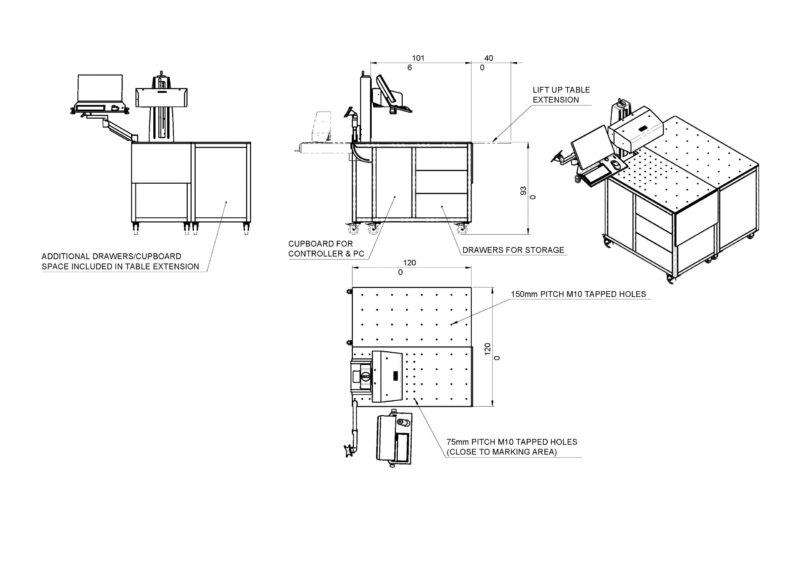

- Standard table size – 1.4m x 0.6m

- Extension table available to increase table size to 1.4m x 1.2m

The Mobile Marking station uses a BenchDot marking head mounted onto a tilting column for ultimate portability and flexibility, it is ideal for low volume, high variety components.

- Features

- Video

Features

Overview

- Dot Peen marking head available in various marking windows: , 150mm x 150mm, 300mm x 150mm

- 1m x 0.6m marking table, with extension to 1.4m x 0.6m

- Optional expansion table to full size of 1.4m x 1.2m

- 75mm pitch M10 tapped holes for fixture attachment

- Tilt from -10° to +90° in 5° increments

- Can operate with embedded control system or PC based software

- Options include circumferential fixture, barcode scan input, deep pneumatic marking head and variety of marking styli to meet IAQG aerospace specifications