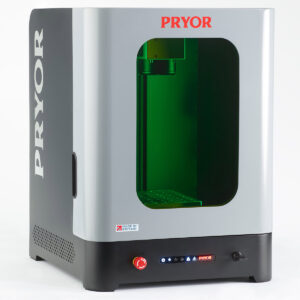

Laser Marking & Engraving Machines

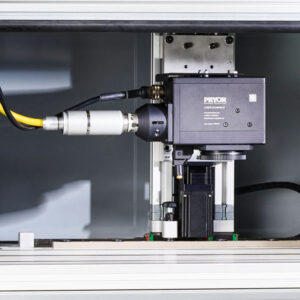

Laser marking and engraving technologies offer precise and permanent solutions for marking various materials including stainless steel, titanium, anodized aluminium, brass, and copper. A laser marking machine utilizes advanced laser technology to imprint enduring marks, designs, or patterns onto diverse surfaces with exceptional speed and accuracy. Widely employed across industrial and manufacturing sectors, laser marking ensures permanent, non-contact markings without compromising material integrity.