Pryor Dot peen marking machines employ a carbide stylus to rapidly create dots on a material's surface, controlled by our Traceability software, Traceable IT. This permanent marking method is utilized for product identification, traceability, and compliance. The process is versatile, allowing for the creation of patterns, alphanumeric characters, and logos, often integrated into automated production lines for efficiency.

Dot peen marking on bikes & motorcycles involves using a stylus to create durable marks on components for traceability, branding, compliance, and anti-theft purposes. It allows motorbike and bike manufacturers to mark unique identification, logos, and certification symbols directly onto frames, aiding in tracking, branding, and meeting regulatory standards. Additionally, it serves as an important anti-theft measure and facilitates customization by marking personalized information on bike components.

Dot peen marking is a permanent process that physically alters the material's surface. The created dots are typically deep enough to ensure durability and long-term legibility, making it suitable for applications requiring lasting identification and traceability.

Dot peen marking is versatile, allowing for marking alphanumeric characters, serial numbers, logos, and other patterns. It's commonly used for product identification, VIN Number marking, branding, compliance marks, and anti-theft codes, offering flexibility for various information types.

Yes, dot peen marking is well-suited for high-volume production. It offers fast and reliable marking, and its integration into automated production lines enhances efficiency, making it a popular choice for industries with large-scale manufacturing needs.

Yes, dot peen marking is widely accepted for traceability in various industries. It meets the requirements of industry standards and regulations, providing a reliable method for marking products with information necessary for tracking and compliance.

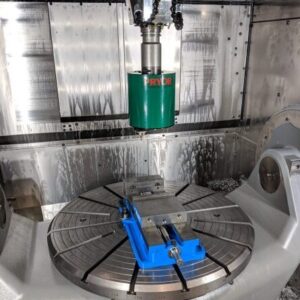

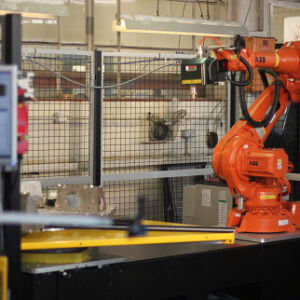

Yes, dot peen markers can be seamlessly integrated into automated production lines. Their computer-controlled systems allow for precise marking, ensuring consistency and efficiency in large-scale manufacturing processes. At Pryor we have been Intargrating marking machines into production lines for many years

Dot peen markers typically have minimal maintenance requirements. Regular checks on the stylus condition and occasional cleaning are common. These systems are designed for durability and reliability, contributing to their suitability for industrial settings. Each location is unique and can have it's own challenges. Please contact our team if you would like to discuss your requirements