BenchDot

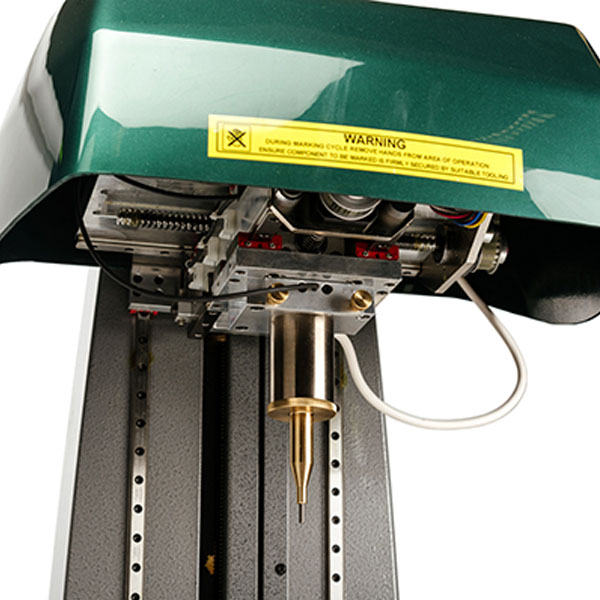

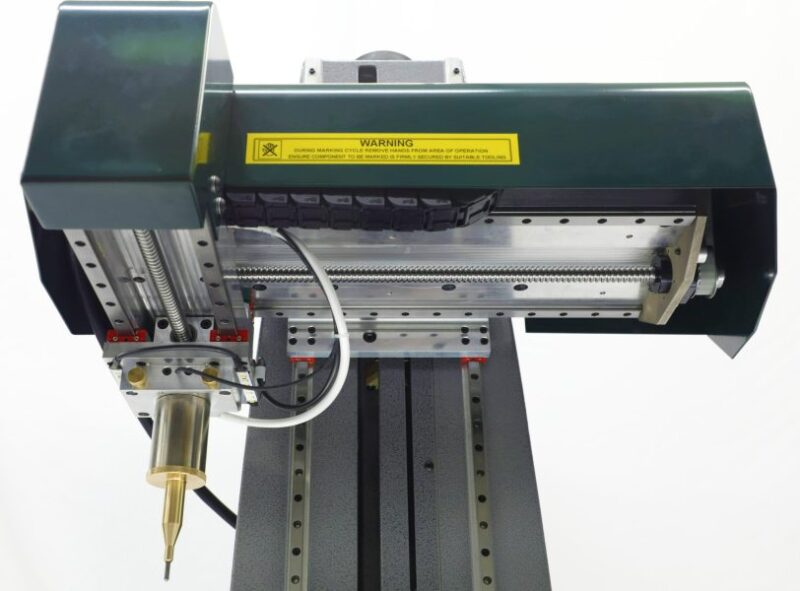

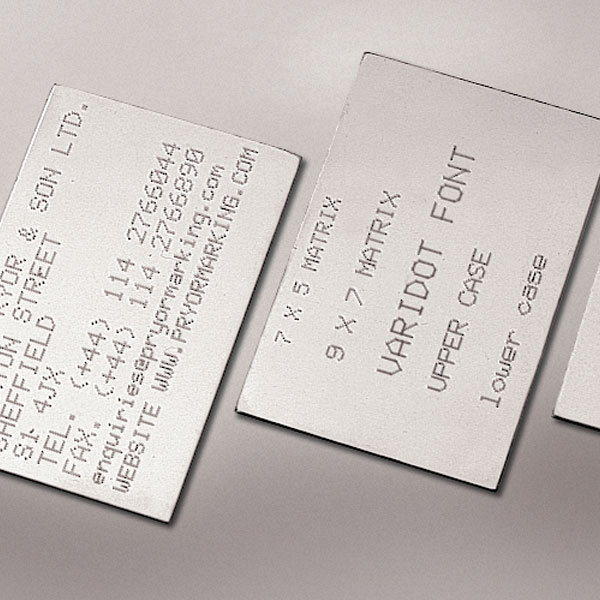

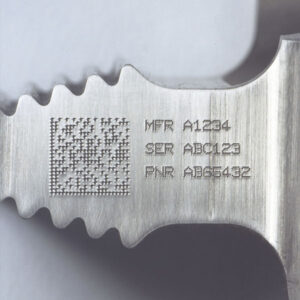

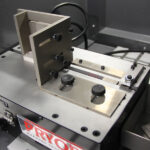

The Pryor BenchDot is a bench mounted dot peen marking machine. These are robust and compact marking devices that can easily integrate into a workshop environment due to their quality build and compact size. The BenchDot is ideal for marking small to medium sized components of unusual shapes and dimensions with alphanumeric information and 2D barcodes.

Programmed using the 4000 Controller or Pryor’s PC based Traceability Software

- Available in 3 different marking window sizes

- A pneumatic version is available for extra deep marking

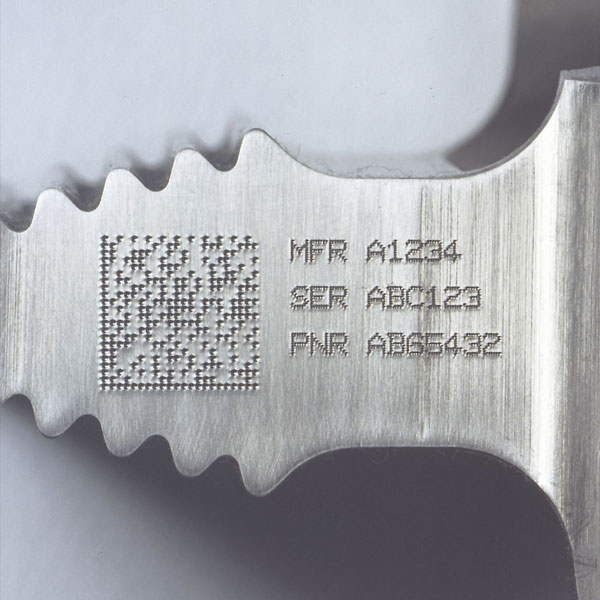

- Ideal for marking alphanumeric identification and Data Matrix codes

- Available with a wide range of accessories to tailor to your specific marking requirements

- Machine of choice for rigorous specifications of data matrix marking in the aerospace industry

- Option to upgrade to an Electric Z Axis with Autosense (EZA) for increased quality control and operator ease

- Widely used within the aerospace industry and military supply chain for marking and verification standards including JES131, MIL-STD-130 and ISO16022.

The Pryor BenchDot is a bench mounted dot peen marking machine. These are robust and compact marking devices that can easily integrate into a workshop environment due to their quality build and compact size. The BenchDot is ideal for marking small to medium sized components of unusual shapes and dimensions with alphanumeric information and 2D barcodes.

- Features

- Deep Pneumatic Version

- Dot Marking in the Aerospace Sector

- Video

Features

- 3 Marking Window sizes:

- 100mm x 100mm

- 150mm x 150mm

- 300mm x 150mm

- Comes with Pryor’s 4000 Controller as standard

- Fully compatible with Pryor’s PC based Traceability Software

- Standard electric version with the option of a pneumatic upgrade if a very deep mark is required

- Machine weight – minimum 40kg (approx. depending on machine size)

- X, Y axis control – Steppermotor driven

- Z axis control – manual adjustment, steppermotor version optional (EZA Upgrade)

- Cable length – 3m standard (other options available upon request)

- Work piece hardness – Max. 62 HRC (800HV)

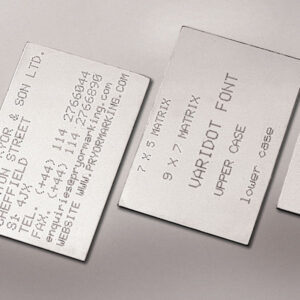

- Character sizes – 0.15mm – 99.9mm in 0.15mm increments

- Memory capacity: up to 9000 inscription layouts

- Controller connectivity options: 1 x RS232, 1 x USB (that has the option of being removed to create 2 x RS232) and digital I/O (8 in 6 out) connectivity. Optional Ethernet TCP/IP and optional Field Bus

- Controller memory capacity: up to 9000 layouts

- Controller features industrial grade 10.4 inch touchscreen with additional option of connecting an external keyboard

- On screen mark preview and trial run features

- Controller dimensions: 375mm x 335mm x 132 mm

- Controller weight: 6.5kg

- Power supply: AC Input 50/60Hz; 100-240VAC

Deep Pneumatic Version

The BenchDot requires no compressed air supply, making it highly efficient and significantly quieter than pneumatically powered systems. For deep marking applications, the machine also provides the option of a Deep Pneumatic Conversion Kit. This will create very deep dot marks that exceeds the basic model capability, up to 1.5mm in mild steel. This is ideal for marking engine blocks and large castings.

Dot Marking in the Aerospace Sector

Aerospace manufacturers and suppliers often choose the option of an added verification system that checks the quality of the codes against international marking standards, including: AS9132, JES131, RRES 90003, AIM-DPM-Guideline, MIL-STD-130, ISO15434 and ISO16022. This verifies that the mark is machine-readable, ensuring that the mark is fit for supplying data in data-driven manufacturing. Pryor also offers the option of adding a Data Matrix reader to the machine, allowing the operator to read and capture data from the marked component. This is critical for data-driven manufacturing and process control, allowing measurability and eliminating quality defects.

The BenchDot is our most popular marking system for the aerospace industry